Description

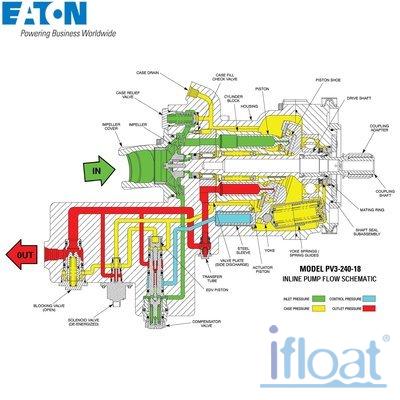

Engine-Driven Pump Model PV3-240-18 for the Boeing 737NG

Eaton's Vickers main Engine-Driven Pump was specifically designed to meet the requirements of the Boeing 737-600/700/800/900

aircraft.

This state-of-the-art engine-driven pump offers superior performance, higher horsepower to weight ratio, and lower operating costs.

The design of the pump is drawn from Eaton's Vickers product line of highly reliable 2.40 cu/in displacement pumps and has significant reduction in weight and volume.

The model PV3-240-18 incorporates the field proven, reliable model PV3-240-2 and PV3-240-10 pump rotating components together with improved reliability and weight reduction technology developed from the Boeing 777 engine-driven pump program.

Many piece parts from the current model PV3-240 production models are incorporated in the new unit, which reduces spare parts inventory requirements.

Design Features

- Increased Fatigue Strength - all castings are designed for improved fatigue characteristics through specific structural design based on finite element analysis and use of improved casting materials -

- Proven Shaft and Yoke Bearings - all bearings used carry the same part numbers as model PV3-240 series, so reducing the spare parts inventory -

- Hollow Drive Shaft - the drive shaft is hollow for weight reduction and the internal surface created by the weight reduction is coated for corrosion control -

- Improved Cylinder Block Material - the cylinder block is machined from ductile iron to minimize wear in the drive spline and piston bores. Bronze plating on the cylinder block surface provides a durable bearing surface for wear against the tool steel valve plate -

- Proven Yoke Design - the yoke used in model PV3-240-18 is an exact 'mirror image' of the field proven model PV3-240-10 series yoke. This is due to the fact that model PV3-240-18 is a counter clockwise rotation unit. All material strength requirements are identical.

- The design allows for the use of mid-grip helical thread locking inserts, eliminating the need for time consuming safety wiring of the shoe retaining plate threaded fasteners -

- Sleeved Actuator Piston Bore - a removable AISI 52100 bearing quality steel provides the bearing surface for the actuator piston -

- Balanced Blocking Valve - the outlet blocking valve is hydraulically balanced for rapid response and ease of manufacture. Viscous dampening of the blocking valve piston retards the closure rate to allow sufficient decompression time for the system outlet fluid prior to valve closure -

- Pressure Compensator - stepped diameter seal glands simplify assembly/disassembly and minimize the risk of seal damage. Double back-up rings provide improved seal support under high pressure conditions. The pressure compensator design also incorporates viscous dampening to improve dynamic stability -

- Centrifugal Boost Impeller - swept blade boost impeller provides higher flow capability, allowing for a smaller size impeller -

- Flange Mounted Electrical Depressurization Valve - the valve is flange-mounted using two threaded fasteners. Step diameter seal glands reduce the possibility of seal damage during assembly -

- Removable Valve Plate - separable valve plate design allows for ease of assemble and optimized material selection -

- Single-piece Housing - the single-piece housing design simplifies maintenance tasks, reduces package weight, and minimizes envelope requirements. Most importantly, it eliminates the parting line between the housing and the valve block - Leakage from the high pressure parting line seals at this interface has traditionally been one of the highest causes of removal of model PV3-240-2 and PV3-240-10 series units -

- Part Commonality - the model PV3-240-18 design utilizes many parts common to other Eaton models. This will reduce the operators' spare part stock requirements.